Facilities

State of the art installation providing services to Aerospace, Medical and Engineering sectors.

Takumi was established in 1998. The company employs 84 staff and occupies a 50,000 sq. ft. custom built facility, complete with assembly area and ample storage to ensure continuity of supply of raw materials and parts. Takumi has unrivalled expertise in the manufacture of low to medium volume precision components.

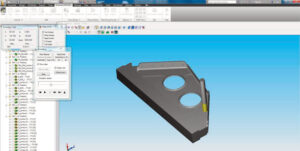

Takumi has 12, four & five axis machining centres, as well as seven CNC lathes. Programming is carried out on the latest version of InventorCAM. This software package has proved to be extremely proficient, particularly for 5 axis work, and is very intuitive and user friendly.

InventorCam Programming

Programming is carried out on the latest version of InventorCAM. This package has proved extremely proficient, particularly for 5 axis work and is very intuitive and user friendly.

Takumi also possess Mastercam X6 as well as Enovia CATIA. We can accept models in all common industry standards including CATIA, IJES, STEP etc.

We have 6 CAM Engineers, working across 2 shifts, giving us the capacity to complete 20-30 new components per week, depending on part complexity.