Equipment

We are well-equipped to deliver for our clients.

Takumi have the widest range of machinery in any company of our sector.

Takumi’s milling cell has 10 machines arranged in an ergonomic and compact square to optimise smooth work throughput. An assortment of 3, 4 and 5 axis machines operate double shift machining a variety of metal implants, instruments and other assorted tooling.

Milling

Make | Model | Spec | |||||

|---|---|---|---|---|---|---|---|

Pallets | Axis | Simult. | Spindles | Tools | Stroke xyz / Spindle Speed | ||

Spinner | U630 | 5 | 4+1 | 1 | 60 | 620-520-460 12000rpm | |

Doosan | DVF5000 | 8 | 5 | Y | 1 | 40 | 625-450-400 18000rpm |

Doosan | DNM 350 5AX | 5 | 1 | 30 | X600-Y655-Z500 12000rpm | ||

Doosan | DNM 350 5AX | 5 | 1 | 30 | X600-Y655-Z500 12000rpm | ||

Doosan | DNM 350 5AX | 5 | 1 | 30 | X500-Y500-Z500 12000 rpm | ||

Matsuura | MX850 | 5 | Y | 1 | 90 | 900-750-680 15000rpm | |

Matsuura | MX520 PC4 | 4 | 5 | Y | 1 | 60 | 630-560-510 12000rpm |

Matsuura | MX520 PC4 | 4 | 5 | Y | 1 | 60 | 630-560-510 12000rpm |

Matsuura | MX520 PC4 | 4 | 5 | Y | 1 | 60 | 630-560-510 12000rpm |

FANUC | Robodrill | 3 | 1 | 21 | 300-400-330 24000rpm | ||

Doosan | VC510 twin pallet | 2 | 3 | 1 | 40 | 762-516-570 12000rpm | |

Doosan | DNM 5700 | 3 | 1 | 30 | 1050-570-510 12000rpm | ||

Doosan | DNM 5700 | 3 | 1 | 30 | 1050-570-510 12000rpm | ||

Doosan | DNM 5700 | 3 | 1 | 30 | 1050-570-510 12000rpm | ||

Doosan | DNM 5700 | 3 | 1 | 30 | 1050-570-510 12000rpm | ||

Doosan | DNM 4500 | 3 | 1 | 30 | 1050-450-510 12000rpm | ||

Doosan | DNM 650 | 3 | 1 | 30 | X650-Y655-Z500 8000rpm | ||

Doosan | DNM 750 2 | 3 | 1 | 30 | 2160-760-650 8000rpm | ||

Doosan | DEM 4000 | 3 | 1 | 30 | 550-400-450 8000rpm | ||

Doosan | DEM 4000 | 3 | 1 | 30 | 550-400-450 8000rpm | ||

Cincinnati | Arrow 750 | 3 | 1 | 21 | X750-Y510-Z500 | ||

Turret Mill | Manual | 3 | 1 | 1 | N/A | ||

Mori Seki VMC | NV5000 | 3 | 1 | 30 | 12000rpm | ||

FANUC | Robodrill | 3 | 1 | 21 | 300-400-330 24000rpm | ||

Matsuura 420 | MX420 | 10 | 5 | Y | 1 | 90 | 420-300 15000rpm |

Matsuura 850 | MX850 | 4 | 5 | Y | 1 | 60 | 850-385 15000rpm |

Turning

Make | Model | Axis | Spindles | Turrets / Plattens |

|---|---|---|---|---|

Doosan | Puma SMX2600 (Millturn) | 5 | 2 | 1 |

Doosan | Puma 2100SY | 6 | 2 | 1/24 |

Doosan | Puma 2600SY | 6 | 2 | 1 |

Doosan | Puma 1800TT | 8 | 2 | 2 |

Doosan | Puma 1800TT | 8 | 2 | 2 |

Doosan | Lynx 300M | 3 | 1 | 1 |

Doosan | Lynx 300M | 3 | 1 | 1 |

Doosan | Lynx | 3 | 1 | 1 |

Deco | 20A | 10 | 4 | 5 Platen/21 |

Deco | Delta 38/5L | 5 | 2 | 3 Platen/31 |

Deco | Delta 38/5L | 5 | 2 | 4 Platen/31 |

Harrison manual lathe | M390GH | 2 | 1 | 1 |

Pinqcho manual lathe | S90/260 | 2 | 1 | 1 |

Fanuc Robot | System R-30iB |

Waterjet

Make | Model | Axis |

|---|---|---|

FLOW | M500 4020 XD | 5 |

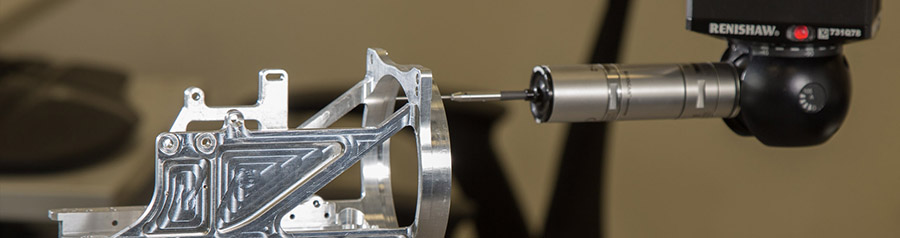

The scale of the capital investment in this area is testament to Takumi’s commitment to quality assurance. Two Mitsutoyo CNC coordinate measurement machines operate on double shift. These machines are complemented by an assortment of other measuring equipment.

QC & Measurement

Make | Model |

|---|---|

Mitutoyo CMM | Cysta Apex S574 CMM |

Mitutoyo CMM | Cysta Apex C544 CMM |

Mitutoyo CMM | Euro C A574 CMM |

Mitutoyo CMM | Crysta Apex 59106 CMM |

Mitutoyo | SJ-310 Surface Tester |

Mitutoyo | SJ-400 Surface Tester |

Tesa | Visio Microscope |

Tesa | Visio CNC Microscope 300DCC |

Tesa | Hite 400 Magna U System |

Baty | R400 Shadowgraph |

System Affri | Hardness Tester 206 RTD |

Tornos | Lunette MA202 Toolsetter |

GBPI | Electronic Tensile Tester |

Ezset | Tool setter |

Haimer | Power Clamp Heatshrink Tooling |

LANG | Makro-Grip |

Mitutoyo CMM | Cysta Apex C574 CMM |

J+L Metrology | Classic-130A |

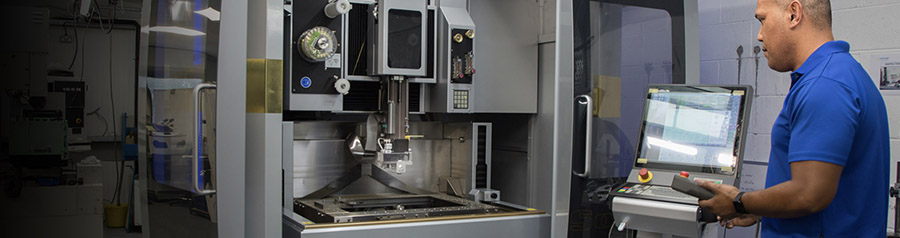

In this cell we are able to produce complex geometries not possible using conventional machining methods. Investment in this “electro discharge machining” technology reflects Takumi`s commitment to providing the ultimate set of capabilities to our customers.

EDM

Make | Model | Axis |

|---|---|---|

AGIE EDM Drill Sparker | Act Spark | 3 |

AGIE EDM Spark Erode | Mondo Star 20 | 4 |

Sodick wire | SLC400 | 5 |

Sodick wire | ALC600G | 5 |

The array of equipment and skills in this cell allows us to meet the requirements set out by the industry. A variety of vibratory bowls, blasting machines and belting and polishing machines allow us to provide a range of finishes ranging from matt to bead blasted to high polish.

Finishing

Make | Model |

|---|---|

Rosler Pressure Pot Blaster (Red) | STD 1000PS |

Typhoon Vacumn Blaster (Blue) | UHBC-1 |

Otec Deburring machine | EF18 |

KKS Parts cleaning machine | 3 bath (ultrasonic with dryer) |

KKS Parts cleaning machine | 3 bath (ultrasonic with dryer) |

KKS Parts cleaning machine | 1 bath (ultrasonic, spin & dry)

|

Walter trowel Rumbler | CD200

|

Walter trowel Rumbler | CD400

|

Walter trowel Rumbler | Mini vibra bowl

|

BMC | HPBS-40/2000 bending press

|

Coldjet | Micro clean ce Blaster |

J&S Engineering | STC250 50 Barprep |

Fladder | 200/Gyro deburring |

Loeses | Belt linisher |

Ciclope | Adair 4-MN-18 Belt linisher |

Ciclope | PLS 400/2-MV-TK Polishing m/c |

Ciclope | DYB3-MVE-TK Deburring |

Airbench | Down draught bench |

Airbench | Down draught bench |

Garboli bar polisher | LPC300Mirror |

Okamoto | PSG52 Grinding |

Jones & Shipman | 540 Grinder |

Ciclope | DYB-1 |

Ciclope | DYB-2 |

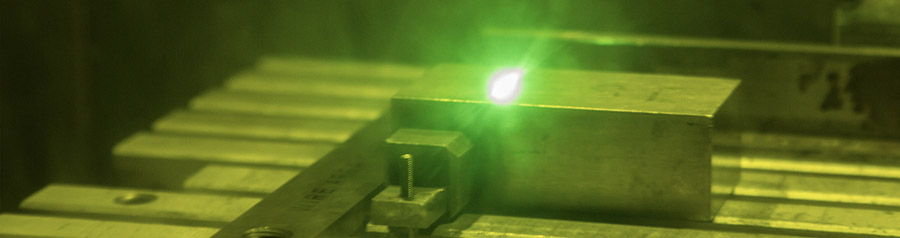

The laser cell was introduced by Takumi to respond to the requirements of the medical industry. Laser engraving allows us to mark components, giving traceability through clear identification. Laser welding allows us to provide neat solutions for joining and fusing complex medical instruments.

Laser

Make | Model | Axis |

|---|---|---|

Rofin laser welder | Select SW1 | 4 |

Rofin laser Engraver | Easy mark | 4 |

Rofin laser Engraver | Easy Mark | 4 |

Epilog laser etcher | Epilog Fusion Edge 12 50w CO2 laser | |

Epilog laser etcher | Epilog Fusion Mini 50w CO2 laser | |

Epilog laser etcher | Epilog Fusion Mini 50w CO2 laser | |

Epilog laser etcher | Epilog Fusion Mini 50w CO2 laser | |

Epilog laser etcher | Epilog Fibremark 20w CO2 laser | |

Epilog laser etcher | Epilog Fibremark 20w CO2 laser | |

Epilog laser etcher | Epilog Fibremark 35w CO2 laser |

Material Handling

Make | Model |

|---|---|

Crane | 3.2T R/C beam with vac lift |

Plate Saw | Zhe Jiang |

Everising | Automatic feed band saw |

Chopsaw | GAA-500-90 |

Chopsaw | GAA-300-90 |

Takumi’s milling cell has 10 machines arranged in an ergonomic and compact square to optimise smooth work throughput. An assortment of 3, 4 and 5 axis machines operate double shift machining a variety of metal implants, instruments and other assorted tooling.

Milling

Make | Model | Spec | |||||

|---|---|---|---|---|---|---|---|

Pallets | Axis | Simult. | Spindles | Tools | Stroke xyz / Spindle Speed | ||

Spinner | U630 | 5 | 4+1 | 1 | 60 | 620-520-460 12000rpm | |

Doosan | DVF5000 | 8 | 5 | Y | 1 | 40 | 625-450-400 18000rpm |

Doosan | DNM 350 5AX | 5 | 1 | 30 | X600-Y655-Z500 12000rpm | ||

Doosan | DNM 350 5AX | 5 | 1 | 30 | X600-Y655-Z500 12000rpm | ||

Doosan | DNM 350 5AX | 5 | 1 | 30 | X500-Y500-Z500 12000 rpm | ||

Matsuura | MX850 | 5 | Y | 1 | 90 | 900-750-680 15000rpm | |

Matsuura | MX520 PC4 | 4 | 5 | Y | 1 | 60 | 630-560-510 12000rpm |

Matsuura | MX520 PC4 | 4 | 5 | Y | 1 | 60 | 630-560-510 12000rpm |

Matsuura | MX520 PC4 | 4 | 5 | Y | 1 | 60 | 630-560-510 12000rpm |

FANUC | Robodrill | 3 | 1 | 21 | 300-400-330 24000rpm | ||

Doosan | VC510 twin pallet | 2 | 3 | 1 | 40 | 762-516-570 12000rpm | |

Doosan | DNM 5700 | 3 | 1 | 30 | 1050-570-510 12000rpm | ||

Doosan | DNM 5700 | 3 | 1 | 30 | 1050-570-510 12000rpm | ||

Doosan | DNM 5700 | 3 | 1 | 30 | 1050-570-510 12000rpm | ||

Doosan | DNM 5700 | 3 | 1 | 30 | 1050-570-510 12000rpm | ||

Doosan | DNM 4500 | 3 | 1 | 30 | 1050-450-510 12000rpm | ||

Doosan | DNM 650 | 3 | 1 | 30 | X650-Y655-Z500 8000rpm | ||

Doosan | DNM 750 2 | 3 | 1 | 30 | 2160-760-650 8000rpm | ||

Doosan | DEM 4000 | 3 | 1 | 30 | 550-400-450 8000rpm | ||

Doosan | DEM 4000 | 3 | 1 | 30 | 550-400-450 8000rpm | ||

Cincinnati | Arrow 750 | 3 | 1 | 21 | X750-Y510-Z500 | ||

Turret Mill | Manual | 3 | 1 | 1 | N/A | ||

Mori Seki VMC | NV5000 | 3 | 1 | 30 | 12000rpm | ||

FANUC | Robodrill | 3 | 1 | 21 | 300-400-330 24000rpm | ||

Matsuura 420 | MX420 | 10 | 5 | Y | 1 | 90 | 420-300 15000rpm |

Matsuura 850 | MX850 | 4 | 5 | Y | 1 | 60 | 850-385 15000rpm |

Make | Model | Axis | Spindles | Turrets / Plattens |

|---|---|---|---|---|

Doosan | Puma SMX2600 (Millturn) | 5 | 2 | 1 |

Doosan | Puma 2100SY | 6 | 2 | 1/24 |

Doosan | Puma 2600SY | 6 | 2 | 1 |

Doosan | Puma 1800TT | 8 | 2 | 2 |

Doosan | Puma 1800TT | 8 | 2 | 2 |

Doosan | Lynx 300M | 3 | 1 | 1 |

Doosan | Lynx 300M | 3 | 1 | 1 |

Doosan | Lynx | 3 | 1 | 1 |

Deco | 20A | 10 | 4 | 5 Platen/21 |

Deco | Delta 38/5L | 5 | 2 | 3 Platen/31 |

Deco | Delta 38/5L | 5 | 2 | 4 Platen/31 |

Harrison manual lathe | M390GH | 2 | 1 | 1 |

Pinqcho manual lathe | S90/260 | 2 | 1 | 1 |

Fanuc Robot | System R-30iB |

Make | Model | Axis |

|---|---|---|

FLOW | M500 4020 XD | 5 |

The scale of the capital investment in this area is testament to Takumi’s commitment to quality assurance. Two Mitsutoyo CNC coordinate measurement machines operate on double shift. These machines are complemented by an assortment of other measuring equipment.

QC & Measurement

Make | Model |

|---|---|

Mitutoyo CMM | Cysta Apex S574 CMM |

Mitutoyo CMM | Cysta Apex C544 CMM |

Mitutoyo CMM | Euro C A574 CMM |

Mitutoyo CMM | Crysta Apex 59106 CMM |

Mitutoyo | SJ-310 Surface Tester |

Mitutoyo | SJ-400 Surface Tester |

Tesa | Visio Microscope |

Tesa | Visio CNC Microscope 300DCC |

Tesa | Hite 400 Magna U System |

Baty | R400 Shadowgraph |

System Affri | Hardness Tester 206 RTD |

Tornos | Lunette MA202 Toolsetter |

GBPI | Electronic Tensile Tester |

Ezset | Tool setter |

Haimer | Power Clamp Heatshrink Tooling |

LANG | Makro-Grip |

Mitutoyo CMM | Cysta Apex C574 CMM |

J+L Metrology | Classic-130A |

In this cell we are able to produce complex geometries not possible using conventional machining methods. Investment in this “electro discharge machining” technology reflects Takumi`s commitment to providing the ultimate set of capabilities to our customers.

EDM

Make | Model | Axis |

|---|---|---|

AGIE EDM Drill Sparker | Act Spark | 3 |

AGIE EDM Spark Erode | Mondo Star 20 | 4 |

Sodick wire | SLC400 | 5 |

Sodick wire | ALC600G | 5 |

The array of equipment and skills in this cell allows us to meet the requirements set out by the industry. A variety of vibratory bowls, blasting machines and belting and polishing machines allow us to provide a range of finishes ranging from matt to bead blasted to high polish.

Finishing

Make | Model |

|---|---|

Rosler Pressure Pot Blaster (Red) | STD 1000PS |

Typhoon Vacumn Blaster (Blue) | UHBC-1 |

Otec Deburring machine | EF18 |

KKS Parts cleaning machine | 3 bath (ultrasonic with dryer) |

KKS Parts cleaning machine | 3 bath (ultrasonic with dryer) |

KKS Parts cleaning machine | 1 bath (ultrasonic, spin & dry)

|

Walter trowel Rumbler | CD200

|

Walter trowel Rumbler | CD400

|

Walter trowel Rumbler | Mini vibra bowl

|

BMC | HPBS-40/2000 bending press

|

Coldjet | Micro clean ce Blaster |

J&S Engineering | STC250 50 Barprep |

Fladder | 200/Gyro deburring |

Loeses | Belt linisher |

Ciclope | Adair 4-MN-18 Belt linisher |

Ciclope | PLS 400/2-MV-TK Polishing m/c |

Ciclope | DYB3-MVE-TK Deburring |

Airbench | Down draught bench |

Airbench | Down draught bench |

Garboli bar polisher | LPC300Mirror |

Okamoto | PSG52 Grinding |

Jones & Shipman | 540 Grinder |

Ciclope | DYB-1 |

Ciclope | DYB-2 |

The laser cell was introduced by Takumi to respond to the requirements of the medical industry. Laser engraving allows us to mark components, giving traceability through clear identification. Laser welding allows us to provide neat solutions for joining and fusing complex medical instruments.

Laser

Make | Model | Axis |

|---|---|---|

Rofin laser welder | Select SW1 | 4 |

Rofin laser Engraver | Easy mark | 4 |

Rofin laser Engraver | Easy Mark | 4 |

Epilog laser etcher | Epilog Fusion Edge 12 50w CO2 laser | |

Epilog laser etcher | Epilog Fusion Mini 50w CO2 laser | |

Epilog laser etcher | Epilog Fusion Mini 50w CO2 laser | |

Epilog laser etcher | Epilog Fusion Mini 50w CO2 laser | |

Epilog laser etcher | Epilog Fibremark 20w CO2 laser | |

Epilog laser etcher | Epilog Fibremark 20w CO2 laser | |

Epilog laser etcher | Epilog Fibremark 35w CO2 laser |

Make | Model |

|---|---|

Crane | 3.2T R/C beam with vac lift |

Plate Saw | Zhe Jiang |

Everising | Automatic feed band saw |

Chopsaw | GAA-500-90 |

Chopsaw | GAA-300-90 |