Takumi’s fully managed and connected supply chain facilitates shot peen, anodize, paint, NDT, passivation, grinding and polishing using a robust ERP system.

1 of 9Complete customer-specific assembly

All components and parts are received ready for use by our customers. Assembly includes swage bearing, stake bearing, rive, nut-plate, isolator, mounting and bushings.

Our Class 7 cleanroom is fully equipped for Medical Device assembly.

2 of 9Our Logistics Department efficiently manages our exports worldwide every day, working closely with our transport agents. Processes around Brexit Customs Regulations are in place to allow seamless transport of stock and materials to and from the UK.

3 of 9We are a team of highly experienced, creative engineers focused on finding the most efficient and cost effective solutions for our customers.

From prototyping, part or complete manufacturing, design consultations through the complete quality and supply chain management process, we work with each customer to find the right solution for their specific manufacturing needs.

Programming is carried out on the latest version of InventorCAM. This package has proved extremely proficient, particularly for 5 axis work and is very intuitive and user friendly.

Takumi also utilises Mastercam X6 as well as Enovia CATIA. We can accept models in all common industry standards including CATIA, IJES, STEP etc.

5 of 9Material stockists for fast turnarounds.

As a materials stockist with our own in-house cutting capability, we eliminate material lead times and reduce turnaround times. Materials stocked include aluminium, plastic, stainless, titanium and a range of exotic materials.

Our cutting-edge machining capabilities include 60+ CNC machines ready to produce the most complex components utilising lights-out manufacturing efficiencies.

7 of 9Rigorous processes using the latest technology

Employing best-practice methodologies, such as: process and machine Validation, Model-Based inspection and CMM Capacity. We use the latest software including: MSCOSMOS, Net-Inspect and Digital FAIR Management.

9 of 9

9 of 9

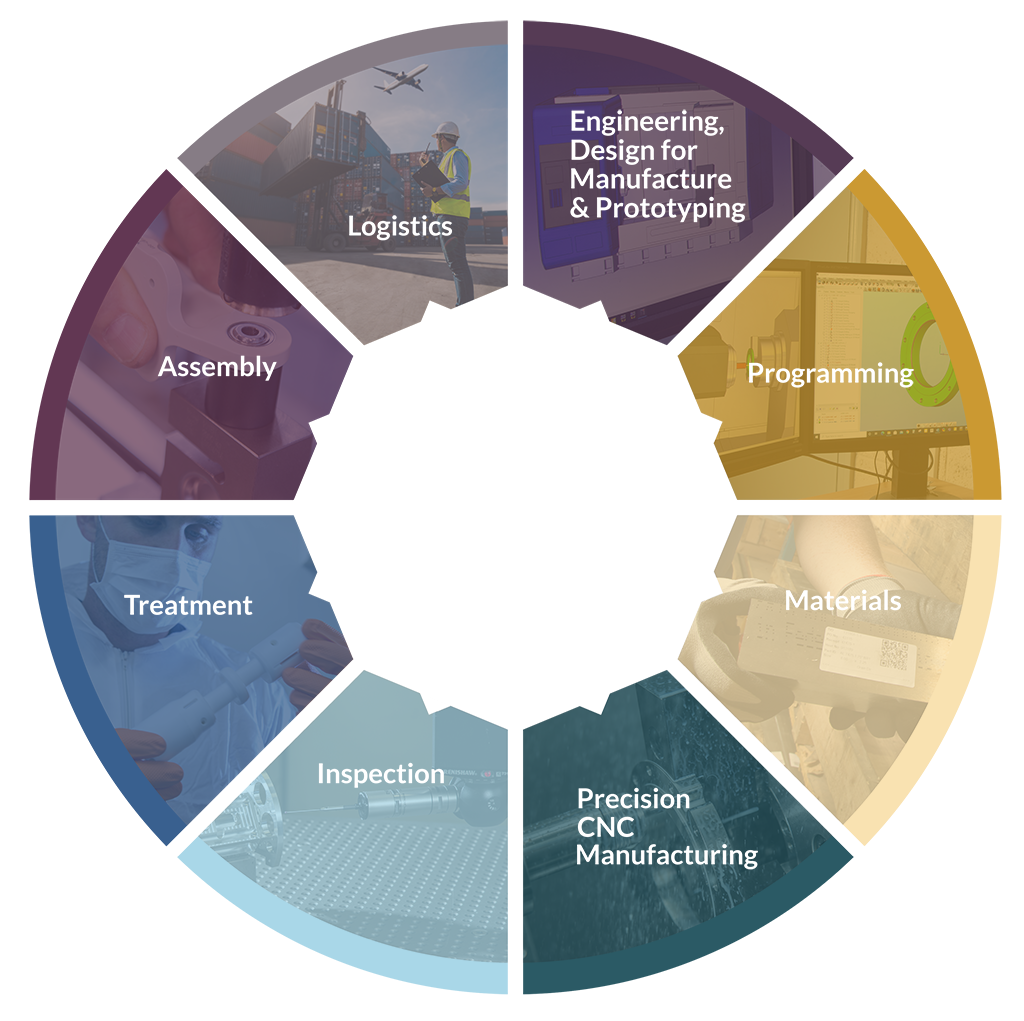

Engineering, Design for Manufacture & Prototyping

We are a team of highly experienced, creative engineers focused on finding the most efficient and cost-effective solutions for our customers.

From design consultation to prototyping to part or complete manufacturing, and through the complete quality and supply chain management process, we work with each customer to find the right solution for their specific manufacturing needs.

Programming

Programming is carried out on the latest version of InventorCAM. This package has proved extremely proficient, particularly for 5 axis work and is very intuitive and user friendly.

Takumi also utilises Mastercam X6 as well as Enovia CATIA. We can accept models in all common industry standards including CATIA, IJES, STEP etc.

Sourcing

and Material

Supply

Material stockists for fast turnarounds.

As a materials stockist with our own in-house cutting capability, we eliminate material lead times and reduce turnaround times. Materials stocked include aluminium, plastic, stainless, titanium and a range of exotic materials.

Precision CNC Manufacturing

Our cutting-edge machining capabilities include 60+ CNC machines ready to produce the most complex components utilising lights-out manufacturing efficiencies.

Our capabilities include:

- 5-axis milling

- 3-axis milling

- Swiss turn

- Mill turning

- Laser welding

- Wire EDM

- Plunge EDM

- Waterjet cutting

Inspection

Rigorous processes using the latest technology

Employing best-practice methodologies, such as: process and machine Validation, Model-Based inspection and CMM Capacity. We use the latest software including: MSCOSMOS, Net-Inspect and Digital FAIR Management.

Treatment

Takumi’s fully managed and connected supply chain facilitates shot peen, anodize, paint, NDT, passivation, grinding and polishing using a robust ERP system.

Assembly

Complete customer-specific assembly

All components and parts are received ready for use by our customers. Assembly includes swage bearing, stake bearing, rive, nut-plate, isolator, mounting and bushings.

Our Class 7 cleanroom is fully equipped for Medical Device assembly.

Logistics

Our Logistics Department efficiently manages our exports worldwide every day, working closely with our transport agents. Processes around Brexit Customs Regulations are in place to allow seamless transport of stock and materials to and from the UK.

Facilities

Takumi was established in 1998. The company employs 84 staff and occupies a 50,000 sq. ft. custom built facility, complete with assembly area and ample storage to ensure continuity of supply of raw materials and parts. Takumi has unrivalled expertise in the manufacture of low to medium volume precision components.

Takumi has 12, four & five axis machining centres, as well as seven CNC lathes. Programming is carried out on the latest version of InventorCAM. This software package has proved to be extremely proficient, particularly for 5 axis work, and is very intuitive and user friendly.